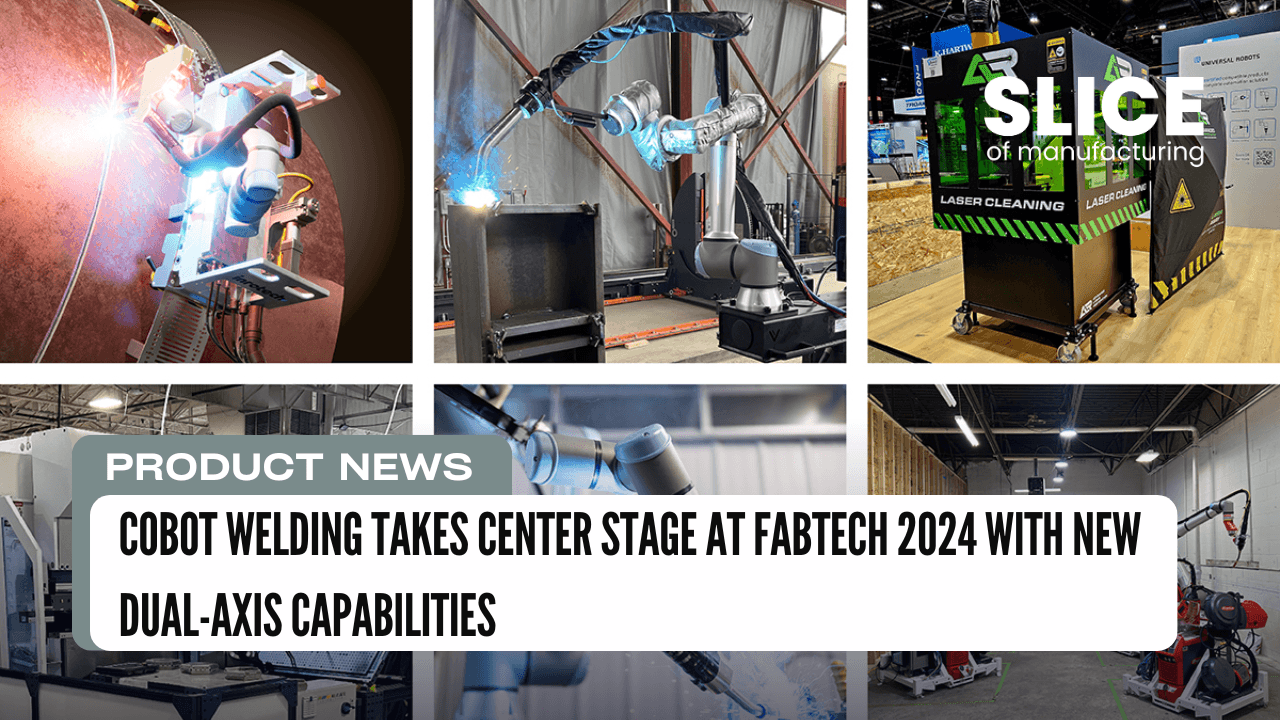

Cobot Welding Takes Center Stage at FABTECH 2024 with New Dual-Axis Capabilities

Key Highlights:

- UR cobots expand into advanced tasks like TIG, laser, and spot welding.

- First dual-axis cobot welding demonstration in North America.

- New MotionPlus package enables multi-axis coordinated motion.

- Portable cobot welders for shipbuilding and construction debut at FABTECH.

- PolyScope X platform simplifies advanced welding automation.

Source: Business Wire

Quotes

“ “UR cobots started out predominantly in air-cooled MIG welding solutions placed on carts. Now we see cobots take on heavier duty tasks such as TIG, laser, and spot welding. Having the cobot sync up with a rotary positioner or linear rail means our customers can now weld parts they normally couldn’t weld efficiently. With portable cobots, industries like shipbuilding now have access to a powerful tool to improve productivity and eliminate repetitive work.” ”

Will Healy III, Global Industry Leader of Welding at Universal Robots

Our Take:

The advancements in cobot welding showcased by Universal Robots at FABTECH 2024 signal a significant leap for the automation industry. The introduction of dual-axis coordinated motion and the expansion of cobot applications beyond MIG welding to more complex tasks like TIG and laser welding provide fabricators with greater flexibility and efficiency. As cobots become more portable and adaptable, industries previously excluded from automation, such as shipbuilding and construction, can now benefit from these cutting-edge technologies. The seamless integration of advanced features like MotionPlus and PolyScope X is set to revolutionize how manufacturers approach productivity and precision in welding tasks.

Expert Insights

Share Your Expert Insights

Have relevant experience or professional perspective? Add your thoughtful insights to this article.