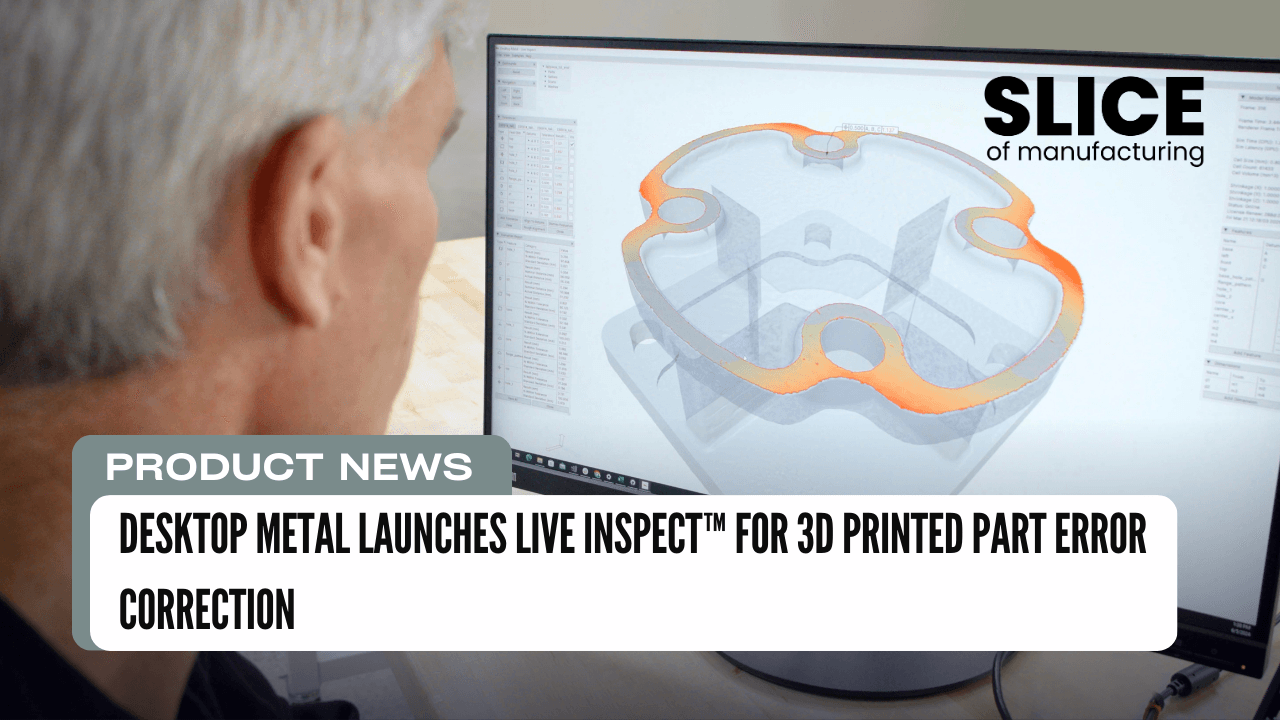

Desktop Metal Launches Live InspectTM for 3D Printed Part Error Correction

Key Highlights:

- Live Inspect™ analyzes and corrects 3D printed part errors.

- Ensures higher tolerances using standard GD&T norms.

- Enhances capabilities for both metal and polymer part manufacturing.

Source (Business Wire)

Quotes

Expert Insights

Share Your Expert Insights

Have relevant experience or professional perspective? Add your thoughtful insights to this article.