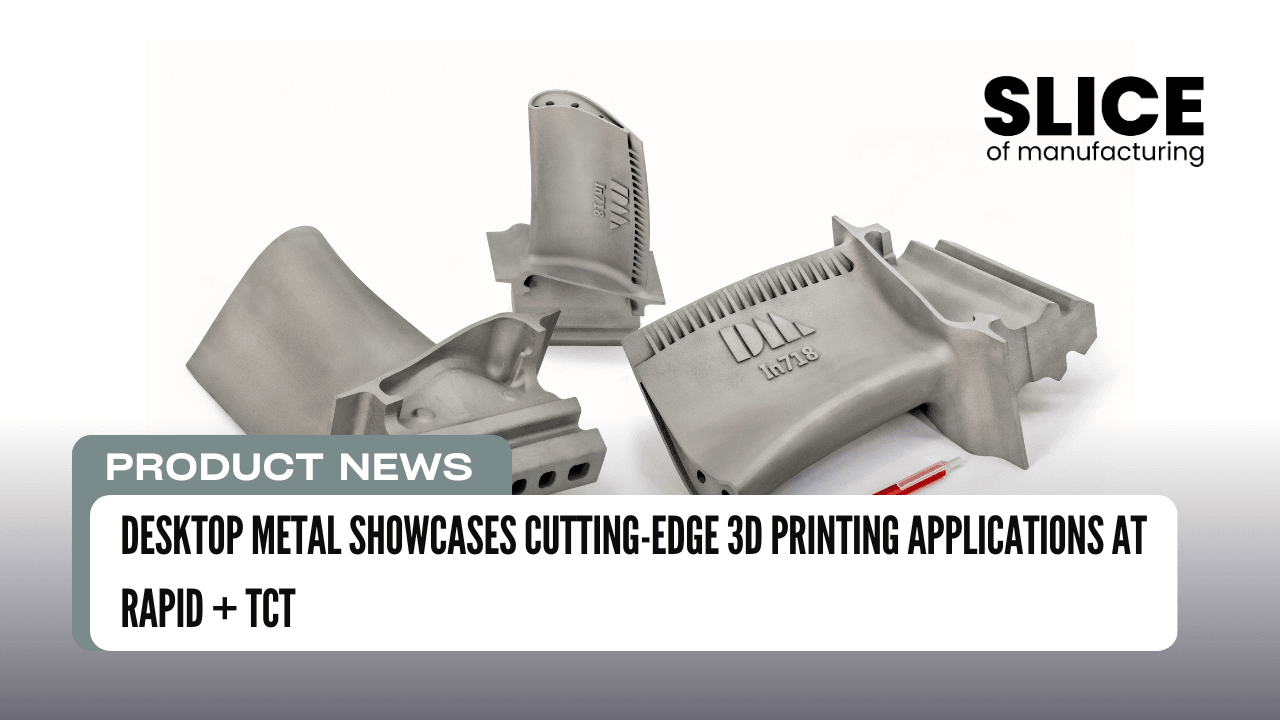

Desktop Metal Showcases Cutting-Edge 3D Printing Applications at RAPID + TCT

Key Highlights:

- Desktop Metal to showcase new 3D printing applications in aerospace, electronics, medical, and consumer goods at RAPID + TCT.

- More than 1,350 Desktop Metal systems installed globally, with over 40 materials qualified for 3D printing.

- Milestone in binder jetting AL6061 powder, achieving performance that rivals traditional investment casting.

- Innovative applications on display, including Silicon Carbide Optical Mirrors, IN718 Turbine Blades, and full sets of golf irons.

- Partnerships and collaborations with leading companies like Eaton Research Labs and Texas Instruments.

Source (Business Wire)

Quotes

Expert Insights

Share Your Expert Insights

Have relevant experience or professional perspective? Add your thoughtful insights to this article.